Table of Contents[hide]

existIndustrial coating field(such as spraying and drying in the automotive, home appliance, metal products and other industries), a large amount of high-temperature organic waste gas and hot air will be generated during the production process, especially inDrying furnace, leveling furnace, pre-treatment heating sectionThere is a lot of waste heat in the flue gas emitted by equipment such asRecovery and utilization of flue gas waste heat, which can significantly reduce energy consumption, improve thermal efficiency, and reduce carbon emissions.

Below fromProcess principleandHow to useTwo aspects are introduced in detail:

1. Process principle of flue gas waste heat recovery

1. Smoke sources and characteristics

-

source:

-

Drying furnace (such as electrophoresis drying, powder spray drying)

-

High temperature leveling furnace

-

Pre-treatment drying section

-

-

Features:

-

The temperature is generally 120°C to 250°C;

-

Contains a certain concentration of volatile organic compounds (VOCs) and a small amount of dust;

-

Usually it is a continuous discharge with a steady flow rate.

-

2. Process principle

Industrial coating flue gas waste heat recovery mainly adoptsIndirect heat exchange principle:

Using special heat exchange equipmentHigh temperature exhaust gas heat transferto air or water medium without direct contact with pollutants.

Main technical routes:

-

Heat pipe heat exchanger:The heat exchange between the media on both sides is realized through efficient heat conduction of heat pipes, which is suitable for high temperature and low pressure difference painting fume.

-

Fin tube heat exchanger: Increase the heat exchange area, often used to heat the air.

-

Hot air recovery system: Use the recovered hot air for fresh air preheating to reduce combustion energy consumption.

-

Indirect water heating system: Flue gas heats circulating water for spraying water, preheating cleaning tank water, etc.

2. Waste heat utilization method

1. Preheating the incoming air (hot air recovery)

-

Application: Air inlet system of drying furnace;

-

Way: The recovered heat is used to heat the cold air through the heat exchanger and used as preheating air for the burner or hot air blower;

-

Effect: It can reduce the gas consumption of 20%~40% and shorten the heating time.

2. Preheating process water

-

Application: Degreasing liquid, cleaning liquid, phosphating liquid, etc. in the pre-treatment line of coating;

-

Way: The waste heat of flue gas heats the circulating water or water storage tank to maintain the temperature of the process tank liquid;

-

Effect:Improve the stability of pre-treatment and save energy consumption of steam or electric heating.

3. Factory heating or hot water supply

-

Way: Use waste heat to heat water and connect it to the HVAC system or hot water system through a heat exchanger;

-

Effect: It can save the operating costs of independent heating systems in winter.

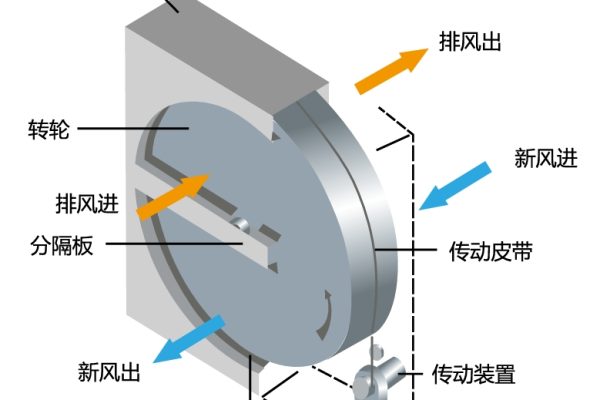

4. Preheating of adsorption concentration wheel

-

Way: In some systems, the VOCs concentration wheel needs to be heated, and the flue gas heat source is used as the energy supply to reduce the electric heating load;

-

Effect: Improve concentration efficiency and reduce energy consumption of treatment system.

5. Waste heat power generation (rare)

-

In large, centralized paint shops, hotter flue gas can be usedOrganic Rankine Cycle (ORC) Low Temperature Power Generation, but the cost is high and it is usually used for super large painting systems.

3. Typical system composition

-

Exhaust gas collection system: Air duct, induced draft fan;

-

Waste heat recovery heat exchanger: Heat pipe, finned tube or plate structure;

-

Intermediate heat circulation system: Circulating water pump, fan, etc.;

-

Heat utilization terminal system: Inlet air preheater, water tank heater, process heating tank, etc.;

-

Intelligent control system: Automatically adjust heat exchange efficiency and heat distribution according to load.