The application of rotary waste heat recovery heat exchanger (also called rotary heat recovery device or heat recovery wheel) in large air volume ventilation equipment has many advantages, especially suitable for large buildings, factory workshops, shopping malls, subway stations and other places. The following are its core application advantages:

1. Efficient heat recovery capability

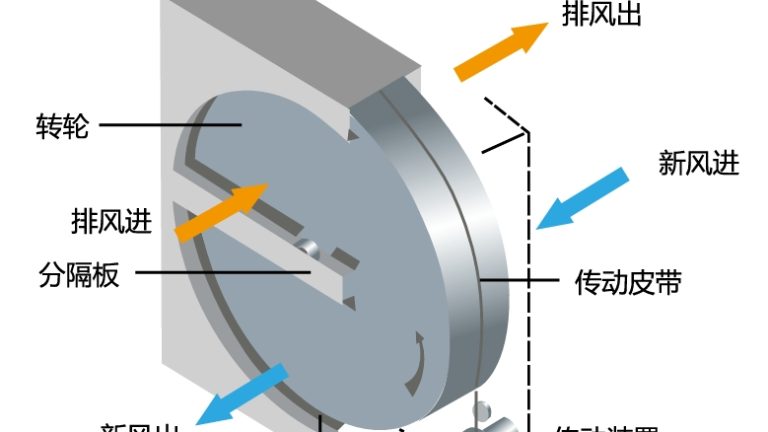

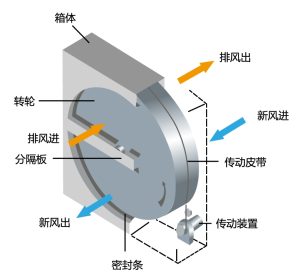

The rotary heat exchanger uses heat storage materials to form the rotor, which has a high heat capacity. When the rotor slowly rotates between the cold and hot air flows, heat transfer is achieved through the process of heat absorption and heat release, and sensible heat and latent heat (latent heat mainly comes from the condensation of water vapor in the humid air) can be recovered at the same time.

Heat recovery efficiency can reach 70%~85%

Compared with plate heat exchangers, higher efficiency under the same conditions

2. Suitable for large air volume systems

The rotary heat exchanger has a compact structure and can handle large air volume per unit volume. It is particularly suitable for handling ventilation volumes of tens of thousands of cubic meters per hour while maintaining low pressure loss.

Can easily handle air volumes over 30,000~100,000 m³/h

Low pressure loss, reducing system energy consumption

3. Save energy and reduce consumption, improve overall energy efficiency

By recovering the heat in the exhaust air to heat or cool the fresh air, the load of the air conditioning system can be significantly reduced, saving operating energy consumption:

Preheat fresh air in winter to reduce heating energy consumption

Pre-cooling fresh air in summer to reduce cooling load

Can significantly reduce air conditioning host capacity and operating costs

4. Recycle humidity (latent heat) to improve air quality

Some wheel materials are hygroscopic (such as molecular sieve coatings), which can achieve humidity transfer during the heat exchange process and are suitable for occasions where there are requirements for indoor humidity control.

Suitable for environments that are sensitive to humidity control, such as hospitals, museums, libraries, etc.

5. Modular structure, easy maintenance

Rotary heat exchangers are usually modular in structure, easy to install and maintain, with fewer moving parts (only the rotor and drive motor) and good stability.

The wheel is detachable and washable, easy to clean

The motor has low energy consumption and low noise

6. Flexible application and strong adaptability

The rotor can be designed as horizontal or vertical according to different building requirements, and is suitable for various wind system layouts. Commonly used for:

Large fresh air handling unit

Energy recovery air conditioning system

Industrial ventilation systems

Summarize

Among large air volume ventilation equipment, rotary waste heat recovery heat exchangers have become an important part of energy-saving ventilation systems in large buildings due to their advantages such as high efficiency, large air volume, recoverable latent heat and wide range of applications. They are particularly suitable for application scenarios where high ventilation needs and high energy efficiency standards are equally important.